- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

S32760 Super Duplex Steel Socket Weld Flanges

Zhejiang Hangong Flange Technology Co., Ltd. is a professional S32760 super duplex steel socket weld flanges manufacturer and supplier in China. Our main projects including stainless steel flanges, duplex steel flanges, super duplex steel flange, pipe fitting manufacturing and sales. We have produced S32760 super duplex steel socket weld flanges for many years, looking forward to reaching a long-term cooperative relationship with you.

Send Inquiry

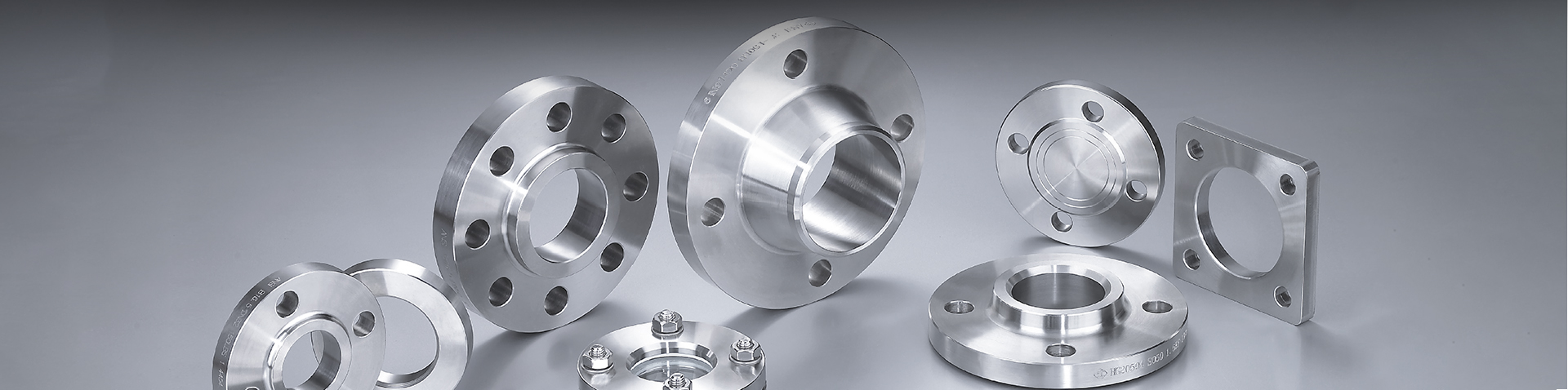

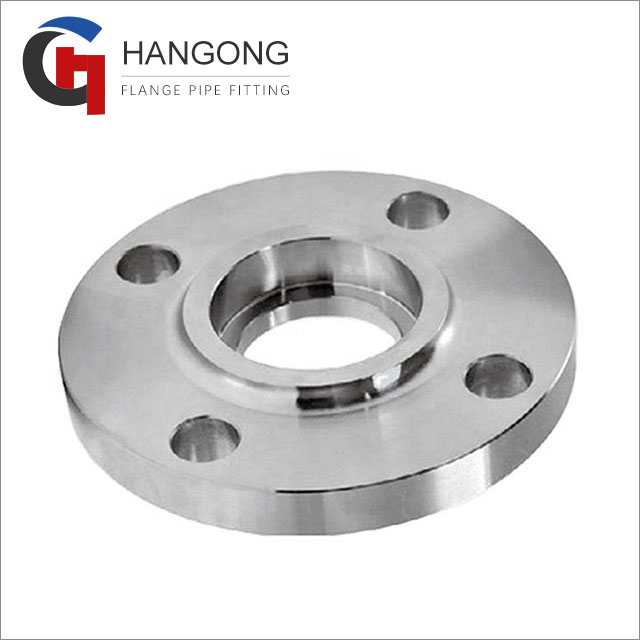

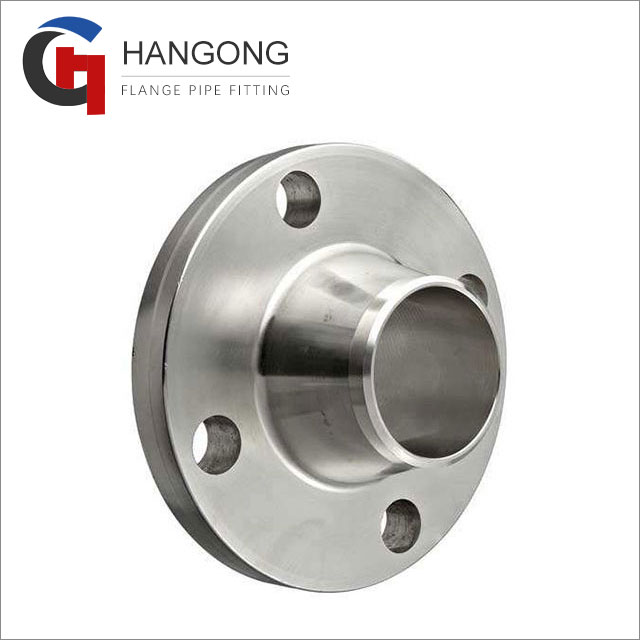

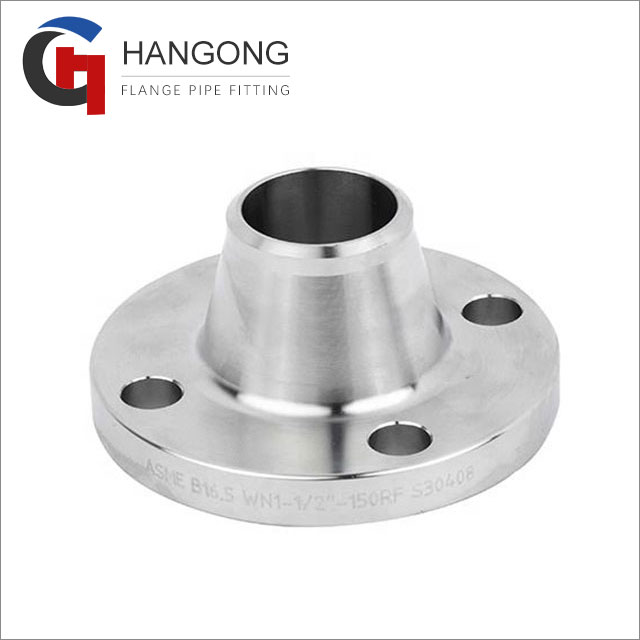

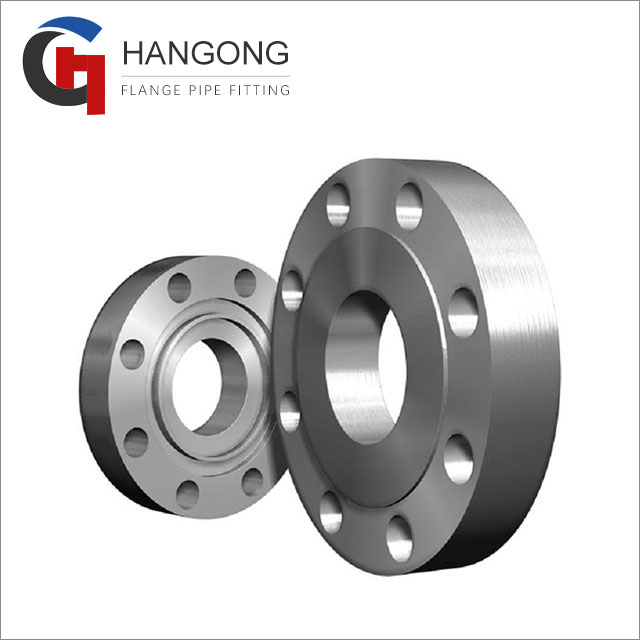

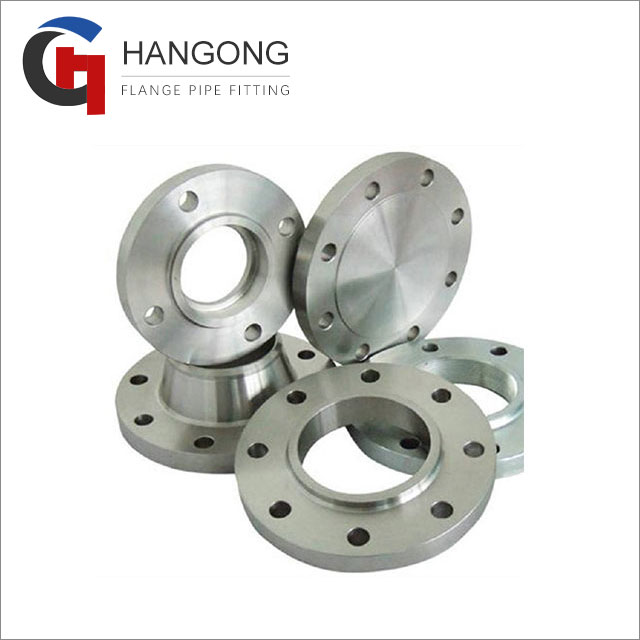

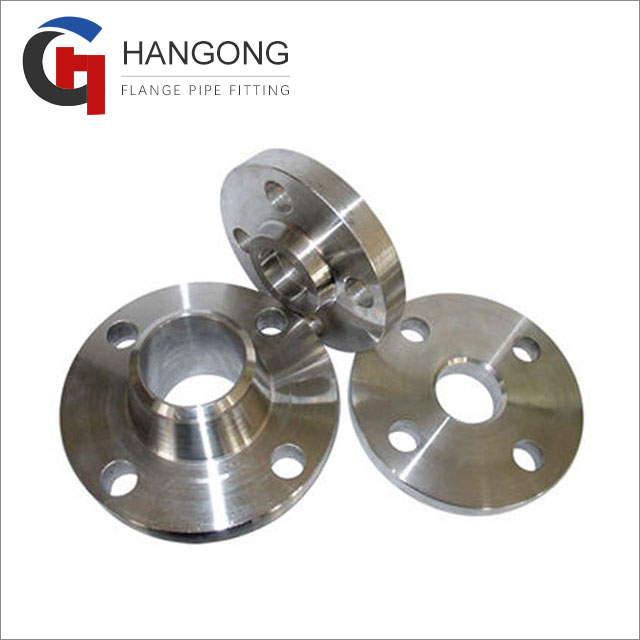

The socket flange is called SW flange for short. The basic shape of the socket flange is the same as that of the flat welding flange with neck, that is, there is a socket hole in the inner hole of the flange, the pipe is inserted into the socket hole and welded, and a circle of welding seam is welded on the back of the flange.

Due to the gap between the socket flange and Caozi, corrosion is easy to occur. The fatigue strength of socket flanges welded on both inner and outer sides is 5% greater than that of flat welded flanges and the static strength is the same. When using the socket flange, its inner diameter shall be consistent with the inner diameter of the pipe. Socket flanges are only suitable for piping of nominal diameter less than 150.

Picture of socket flange:

Parameter (Specification) of S32760 Super Duplex Steel Socket weld Flanges

|

Name |

rtj scrd socket weld shaft slip on flange pipe carbon steel slanting forging slip blind flanged bits |

|

|

Type |

Welding Neck Flange,Plate Flange,Slip on flange,Blind Flange,Threaded Flange,Socket Welding Flange |

|

|

Standard |

ANSI |

ANSI B16.5 ASME B16.47 series A/B |

|

DIN |

DIN |

|

|

GOST |

GOST 12820-80/GOST 12821-80/GOST 12822-80/ |

|

|

EN |

EN1092-1:2002 |

|

|

JIS |

JIS B2220-2004, KS D3576, KS B6216 KS B1511-2007 JIS B2261; JIS B8210 |

|

|

BS |

BS4504 BS10 Table D/E |

|

|

Material |

ANSI |

CS A105/SA 105NSS 304/304L, 316/316L Alloy Steel: WHPY45/52/65/80 |

|

DIN |

CS RST37.2;S235JR SS 304/304L,316/316L |

|

|

GOST |

CS CT20;16MN;SS 304/304L,316/316L |

|

|

EN |

CS RST37.2;S235JR;C22.8SS 304/304L,316/316L |

|

|

JIS |

SS400,SF440 SS 304/304L, 316/316L |

|

|

BS |

CSRST37.2;S235JR;C22.8;Q235SS 304/304L,316/316L |

|

|

Pressure |

ANSI |

Class 150, 300, 600, 900, 1500 2500lbs |

|

DIN |

PN6,PN10,PN16,PN25,PN40,PN64,PN100 |

|

|

GOST |

PN6,PN10,PN16,PN25,PN40,PN64,PN100 |

|

|

EN |

PN6,PN10,PN16,PN25,PN40,PN64,PN100 |

|

|

JIS |

1K,2K,5K,10K,16K,20K,30K,40K |

|

|

BS |

PN6,PN10,PN16,PN25,PN40,PN64,PN100 |

|

|

Size |

ANSI |

1/2” – 60” |

|

DIN |

DN15-DN2000 |

|

|

GOST |

DN15-DN1600 |

|

|

EN |

DN15-DN2000 |

|

|

JIS |

15A-1500A |

|

|

BS |

DN15-DN2000 |

|

|

Coating |

varnish, yellow paint, anti-rust oil, galvanizing etc |

|

|

Usage |

varnish, yellow paint, anti-rust oil, galvanizing etc |

|

|

Water works, Shipbuilding industry, Petrochemical & Gas industry, Power industry, Valve industry,and general pipes connecting |

||

|

customization |

customization |

|

Major differences of S32760 Super Duplex Steel Socket weld Flanges

1. Fillet welds are formed by socket welding, and butt welds are formed by butt welding. The analysis of butt joint from the strength and stress of the weld is better than that of socket and socket, so it is appropriate to adopt the form of butt joint in the occasion of high pressure grade and bad use condition.2. Socket welding is generally used for small pipe diameter less than or equal to DN40, which is more economical. Butt welding is generally used for DN40 and above. The connection form of socket welding is mainly used in the welding of small diameter valves and pipes, pipe fittings and pipes. Small diameter pipe generally has thin wall thickness, easy to mis-edge and ablative, and is more difficult to butt welding, so it is more suitable for socket welding. In addition, the socket of socket welding has the role of reinforcing, so it is also used under high pressure.

However, socket welding also has disadvantages. One is that the stress condition after welding is not good, welding is easy to occur, and there are gaps in the pipe system. Therefore, socket welding should not be used for the pipe system with crevice corrosion sensitive medium and the pipe system with high cleanliness requirements. Moreover, ultra-high pressure pipes, even small diameter pipe wall thickness is also very large, can be butt welding connection as far as possible to avoid socket welding.

3. The diameter of the former must be large and small before insertion and welding. The latter diameter can be the same or not the same. 2. The welding groove form is not the same. 3. The welding process is different. The strength is not the same after welding.

4. Those with lower pressure levels and smaller calibers are mostly socket welding, while those with higher pressure levels are often butt welding. Butt welding shall be tested 100% to ensure no leakage.

5. As the name implies, socket welding is to insert the pipe into the welding, and butt welding is directly relative to the pipe mouth welding. Generally, butt welding has higher requirements than socket welding, and the quality after welding is good, but the detection means are relatively strict. For butt welding, X-ray testing is required. For socket and socket welding, magnetic powder or penetration testing can be done (like carbon steel for magnetic powder and stainless steel for penetration). If the fluid in the pipe does not have high welding requirements, you are advised to use socket welding for easy detection

S32760 Super Duplex Steel Socket weld Flanges Produce

1. Each flange or pipe fittings is wiped after ultrasonic cleaning.

2. Each flange or pipe fittings is individually packaged with bubble protective film and placed in a wooden box.

3. All products are packed in plywood boxes. For larger size flanges, packed in plywood pallets. Or you can customize the packaging by yourself.

4. Shipping marks can be made as required

5. Product label can be engraved or printed. Accept OEM.

FAQ

Q: Can you accept L/C deferred 30, 60, 90days?

A: We can.

Q: Can you supply invoice and CO with chamber of commerce?

A: Yes, we can supply.

Q: Can you supply Form e, Cerficiate of origin?

A: Yes, we can supply.

Q: Can you accept O/A payment?

A: We can.

Q: Can you supply samples?

A: Yes, some samples are free.