- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

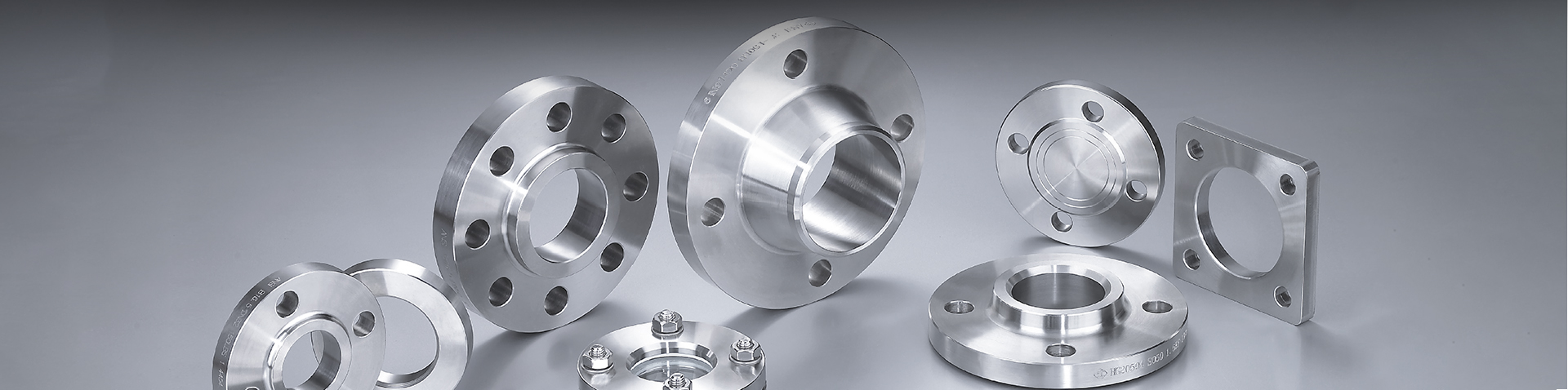

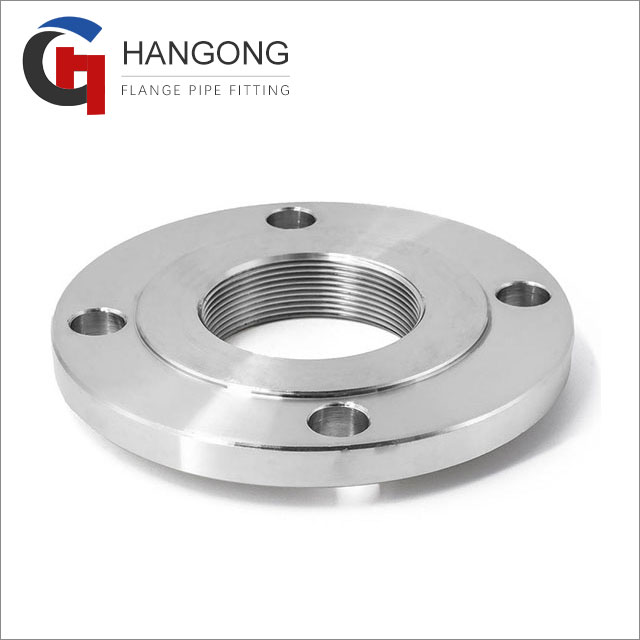

Duplex Steel S31803 Threaded Flanges

Duplex steel S31803 threaded flanges is a kind of flange connected with the pipe by the thread. Design, according to the loose flange treatment. The advantage is that there is no need to weld, flange deformation on the cylinder or pipe generated additional torque is small. The disadvantage is that the flange thickness is large and the cost is high. Suitable for high pressure pipeline connection.

Send Inquiry

The following is an introduction to duplex steel S31803 threaded flanges, I hope to help you better understand duplex steel S31803 threaded flanges. Welcome new and old customers to continue to cooperate with us to create a better future together! We hope to establish friendly cooperative relationship with your company with high quality products, reasonable price, considerate service and create a better future hand in hand.

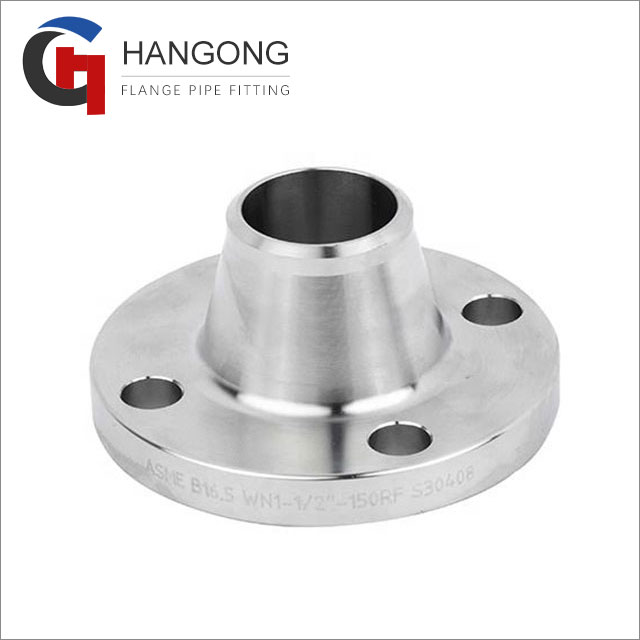

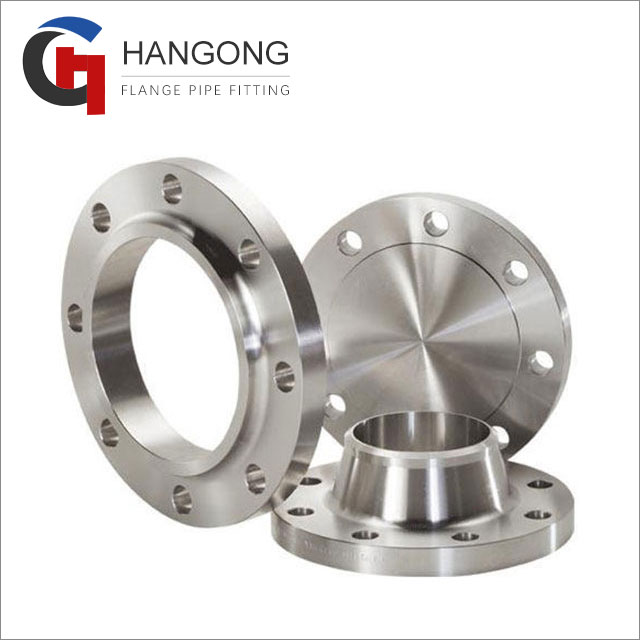

Parameter (Specification) of Duplex Steel S31803 Threaded Flanges

|

Size |

ASME B16.5:1/2"-24" ASME B16.47:26"-48" |

|

Rating |

150LB/300LB/600LB/900LB/1500LB/2500LB |

|

Standard |

ASME B16.5, ASME B16.47A, ASME B16.47B, MSS SP 44, DIN 2632, DIN2633, DIN2634, DIN2635, DIN2636, JISB2220, BS4504, GB, etc |

|

Material |

1. Carbon steel: A105, A350 LF2, A694 F52, F65, Q235 etc. 2. Stainless steel: ASTM A182 F304, 304L, 316, 316L, 321, 1Cr18Ni9Ti, 00Cr19Ni10, A182 F51, F53, F55 etc. |

|

Surface |

Black Painting / Anti Rust Oil / Hot Dip Galvanized |

|

Certification |

ISO 9001:2015 |

|

Packing |

Plywood cases, pallets, or as per your request. |

|

Application |

Petroleum, chemical, machinery, electric power, shipbuilding, papermaking, construction etc |

|

Port of delivery |

Shanghai port, Xingang port, Xiamen port, Ningbo port etc. |

Principle of Implementation Duplex Steel S31803 Threaded Flanges

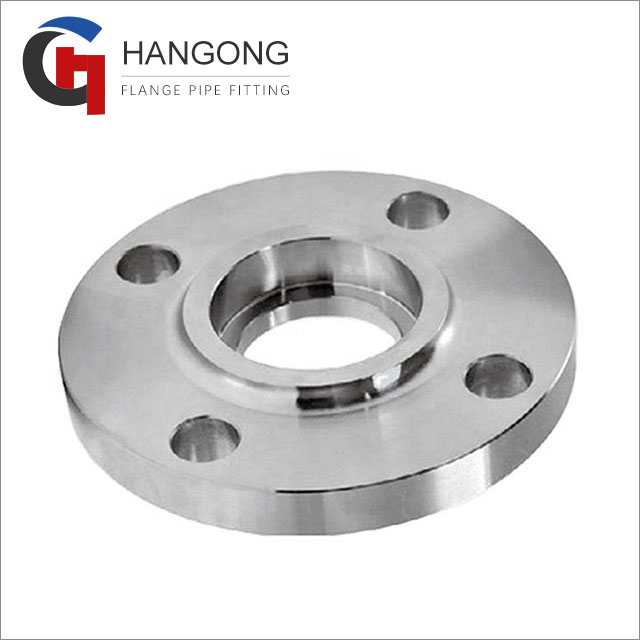

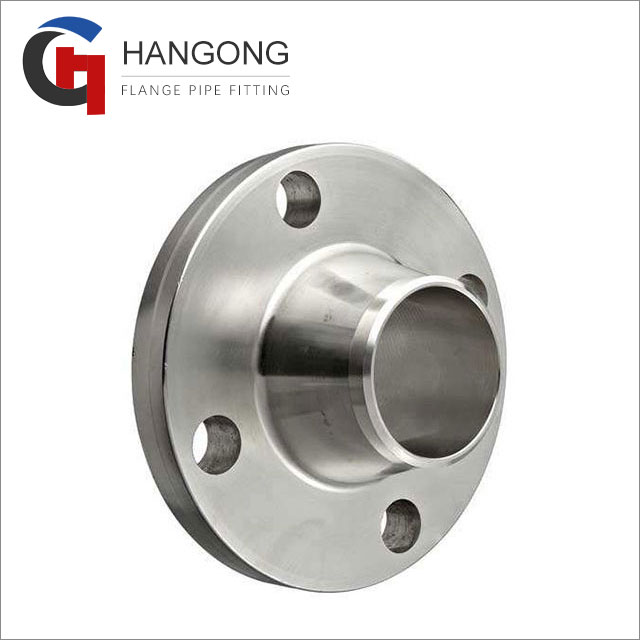

Duplex Steel S31803 Threaded Flanges is the inner hole of the flange is processed into pipe thread, and with threaded pipe matching connection, is a kind of non-welded flange. Compared with welding flanges or butt flanges, threaded flanges are easy to install and maintain, and can be used in some pipelines where welding is not allowed on site.

Alloy steel flanges have sufficient strength, but not easy to weld, or welding performance is not good, you can also choose threaded flanges. However, when the pipe temperature changes rapidly or the temperature is higher than 260 ° C and lower than -45 ° C, you are advised not to use threaded flanges to avoid leakage.