- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

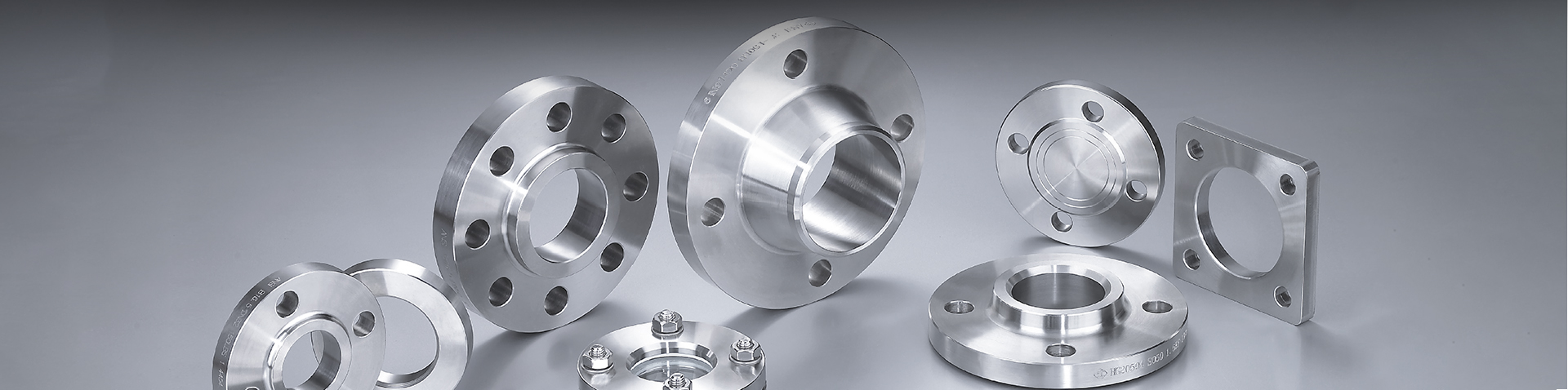

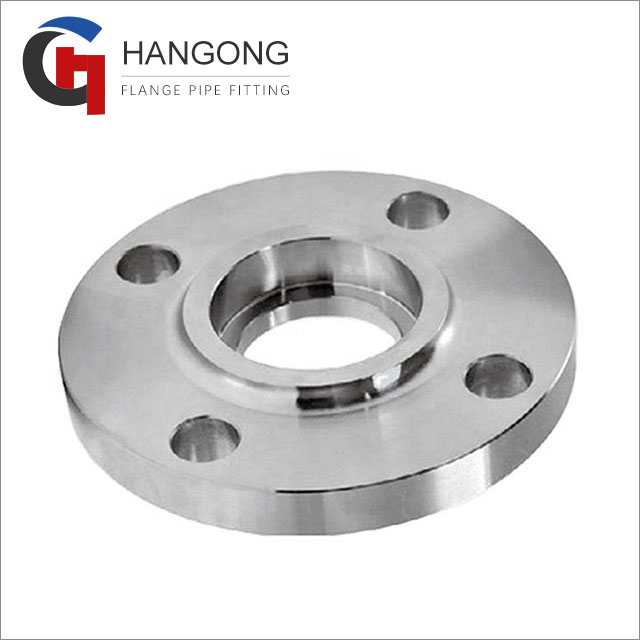

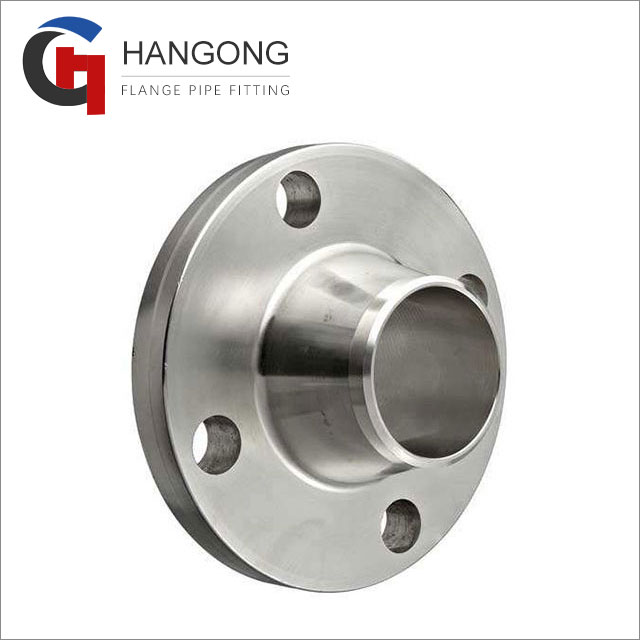

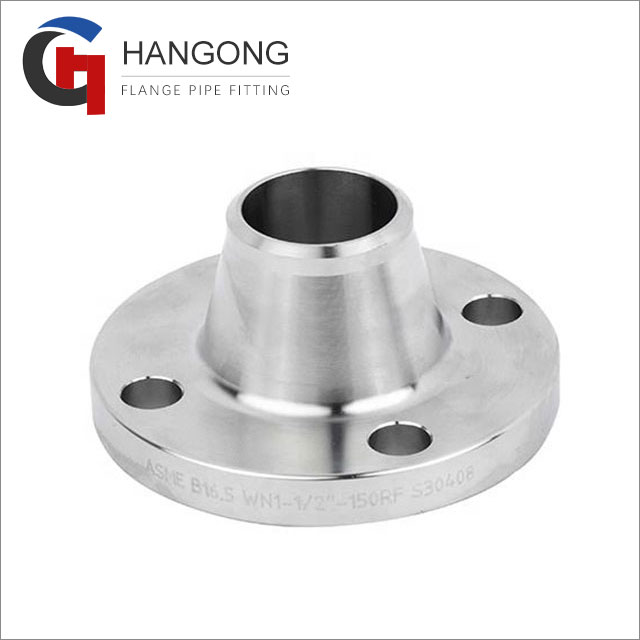

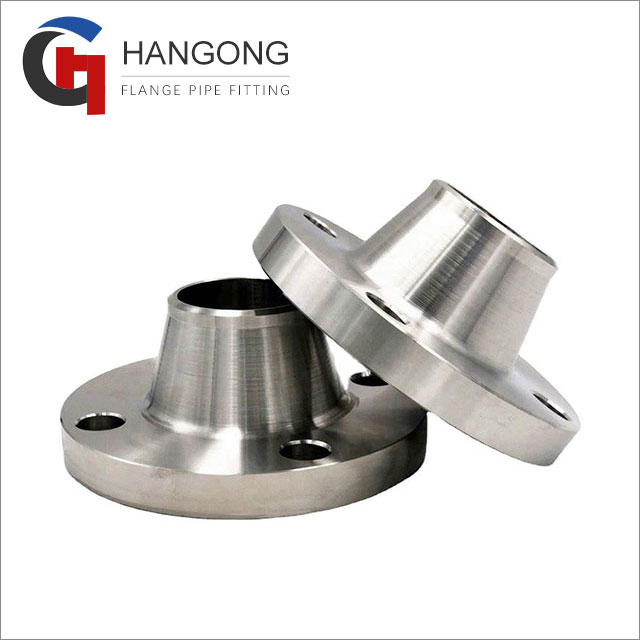

Duplex Steel S31803 Socket Weld Flanges

Zhejiang Hangong Flange Technology Co., Ltd. is a professional duplex steel S31803 socket weld flanges manufacturer and supplier in China. Our main projects including stainless steel flanges, duplex steel flanges, super duplex steel flange, pipe fitting manufacturing and sales. We have produced duplex steel S31803 socket weld flanges for many years, looking forward to reaching a long-term cooperative relationship with you.

Send Inquiry

Duplex steel S31803 socket weld flanges , as the name suggests is a biphasic steel bar, steel ingot or plate such as the production of raw materials for the flange, referred to as biphasic steel flange, flange is also called flange or protruding edge. It is the part that connects the pipe to the pipe. Connected to tube end.

There are holes on the flange, and the bolts can be worn to make the two flanges tightly connected. The flanges are gasketed. The flange connection consists of a pair of flanges, a gasket and a number of bolts and nuts. The gasket is placed between the sealing surface of the two flanges.

After tightening the nut, the specific pressure on the surface of the gasket will be deformed after reaching a certain value, and the uneven part of the sealing surface will be filled to make the connection tight without leakage. Some pipe fittings and equipment have their own flanges, which are also flange connections. Flange connection is an important connection mode in pipeline construction.

Parameter (Specification) of Duplex Steel S31803 Socket weld Flanges

|

Standard |

Type |

Class |

Size |

|

ASME B16.5 |

WN/LWN/SO/Blind/Lap Joint |

150#-2500# |

1/2"-24" (Except Blind Flange 2500lb 1/2"-12") |

|

SW flange |

150#-1500# |

1/2"-3" (Except 1500# 1/2"-2 1/2") |

|

|

Threaded |

150#-900# |

1/2"-24" |

|

|

1500# 2500# |

1/2"-2 1/2" |

||

|

ASME B16.47 Series A |

WN/blind flange |

150# -900# |

22"-48" (Except 900# Size:26"-48") |

|

ASME B16.47 Series B |

WN/blind flange |

75#-300# |

26"-48" |

|

400# 600# 900# |

26"-36" |

||

|

DIN2527 |

Blind flange |

PN6-PN100 |

DN10-DN1000 |

|

DIN2543 |

SO flange |

PN16 |

DN10-DN1000 |

|

DIN2544 |

SO flange |

PN25 |

DN10-DN1000 |

|

DIN2545 |

SO flange |

PN40 |

DN10-DN500 |

|

DIN2565 |

Threaded flange with Neck |

PN6 |

DN6-DN200 |

|

DIN2566 |

Threaded flange with Neck |

PN16 |

DN6-DN150 |

|

DIN2567 |

Threaded flange with Neck |

PN25 PN40 |

DN6-DN150 |

|

DIN2568 |

Threaded flange with Neck |

PN64 |

DN10-DN150 |

|

DIN2569 |

Threaded flange with Neck |

PN100 |

DN10-DN150 |

|

EN1092-1:2002 |

Plate flange for welding/ loose plate flange with weld-on plate collar or for lapped pipe end/Blind Flange/WN flange |

PN2.5-PN100 |

DN10-DN4000 |

|

JIS B2220 |

Welding flange, lap joint flange, threaded flange |

PN6-PN100 |

DN10-DN1500 |

|

BS4504 BS10 TableD/E |

Plate Flange for welding/ WN flange/blank Flange |

PN6-PN100 |

DN10-DN1500 |

|

Other Products |

Anchor/swivel/girth/l ap joint/reducing/orifice |

||

|

Spectacle blind/paddle blind/ spacer ring/orifice plate/bleed ring |

|||

|

Special Products: rings/ forgings/disc/shaft sleeves |

|||

|

Sealing Surface |

RF FF RTJ TF GF LF LM |

||

|

Flange Face Finish |

Stock finish/spiral serrated/ concentric serrated/smooth finish (Ra 3.2 and 6.3 micrometers) |

||

|

125-250 AARH(it is called smooth finish) |

|||

|

250-500 AARH(it is called stock finish) |

|||

|

Coating |

Vanish, yellow paint, anti-rust oil, galvanizing etc |

||

|

Material Grade |

Nickel Alloy Steel |

ASTM/ASME B/SB564 UNS N02200(NICKEL 200), UNS N04400(MONEL 400), |

|

|

UNS N08825( INCOLOY 825),UNS N06600(INCONEL 600), |

|||

|

UNS N06601(INCONEL 601), UNS N06625(INCONEL 625), UNS N10276(HASTELLOY C276), |

|||

|

ASTM/ASME B/SB160 UNS N02201(NICKEL 201), ASTM B/SB472 UNS N08020(Alloy 20) |

|||

|

Copper Alloy |

ASTM/ASME B/SB151 UNS C70600(CuNi 90/10), C71500(CuNi 70/30) |

||

|

Stainless Steel |

ASTM/ASME A/SA182 F304,304L,304H,309H,310H, 316,316H,316L,316LN, |

||

|

317,317L,321,321H,347,347H |

|||

|

Duplex and Super Duplex Steel |

ASTM/ASME A/SA182 F44,F45,F51,F53,F55,F60,F61 |

||

|

Carbon steel |

ASTM /ASME A/SA105(N) |

||

|

Low Temp Carbon Steel |

ASTM/ASME A/SA350 LF2 |

||

|

High Yield Carbon Steel |

ASTM/ASME A/SA694 F52,F56 F60, F65, F70 |

||

|

Alloy Steel |

ASTM/ASME A/SA182 GR F5, F9, F11,F12,F22,F91 |

||

|

Titanium |

ASTM/ASME B/SB381 Grade 2, Grade 5, Grade 7 |

||

Raw materials of Duplex Steel S31803 Socket weld Flanges

Biphasic steel flange uses biphasic steel as raw material for production, the so-called biphasic stainless steel is in the solid solution of its ferrite phase and austenitic phase about half, the general amount of small phase content also needs to reach 30%. When the content of C is low, the content of Cr is 18%-28% and the content of Ni is 3%-10%. Some steels also contain Mo, Cu, Nb, Ti, N and other alloying elements.

This kind of steel has the characteristics of austenitic and ferritic stainless steel, compared with ferrite, plasticity, toughness is higher, no room temperature brittleness, intergranular corrosion resistance and welding performance are significantly improved, but also maintain the ferritic stainless steel 475℃ brittleness and high thermal conductivity, with superplasticity and other characteristics. Compared with austenitic stainless steel, it has higher strength and better resistance to intergranular corrosion and chloride stress corrosion. Duplex stainless steel has excellent corrosion resistance, is also a nickel nickel stainless steel.